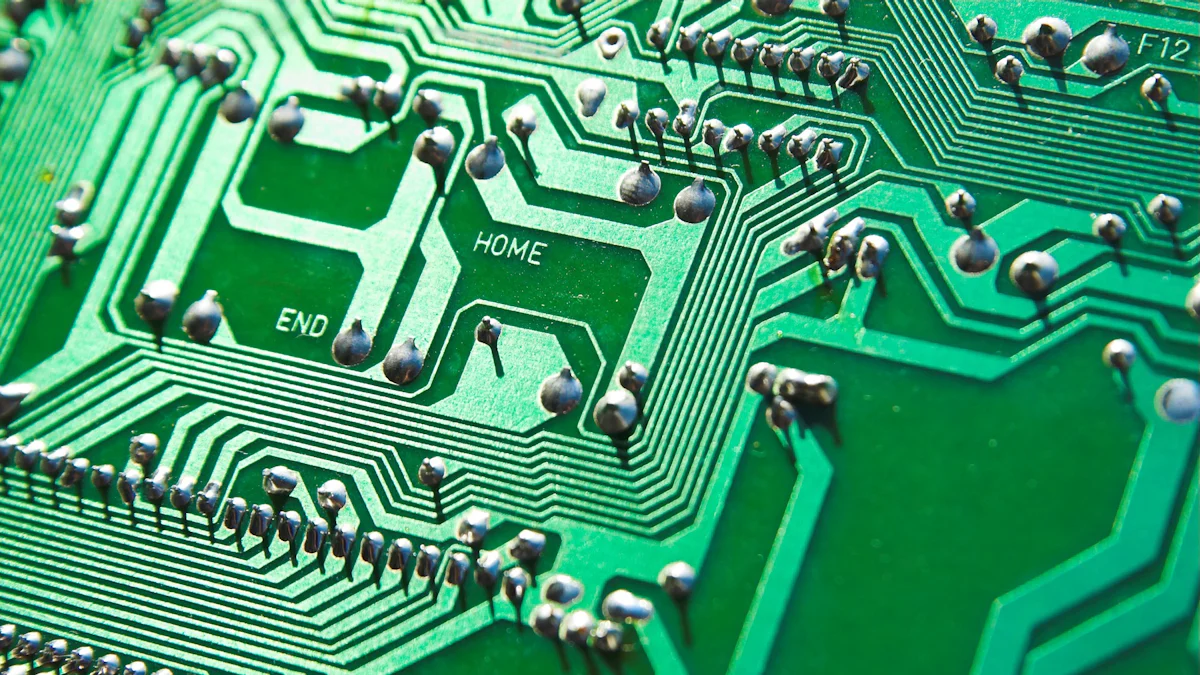

Unveiling the Top Advantages of Rigid PCBs in Electronics

Rigid PCBs, also known as Printed Circuit Boards, play a crucial role in modern electronics. These boards provide a sturdy foundation for electronic components to function seamlessly. Their significance lies in their ability to enhance the performance and reliability of electronic devices. This blog will delve into the advantages and applications of Rigid PCBs, shedding light on their pivotal role in shaping the future of electronics.

Advantages of Rigid PCBs

Durability and Reliability

Rigid PCBs exhibit exceptional mechanical strength, ensuring that the boards can withstand external pressures and support the components effectively. This feature is crucial in applications where the board needs to bear weight or endure physical stress.

One of the key advantages of rigid PCBs is their thermal stability. These boards efficiently dissipate heat, preventing overheating issues and ensuring optimal performance even in demanding environments.

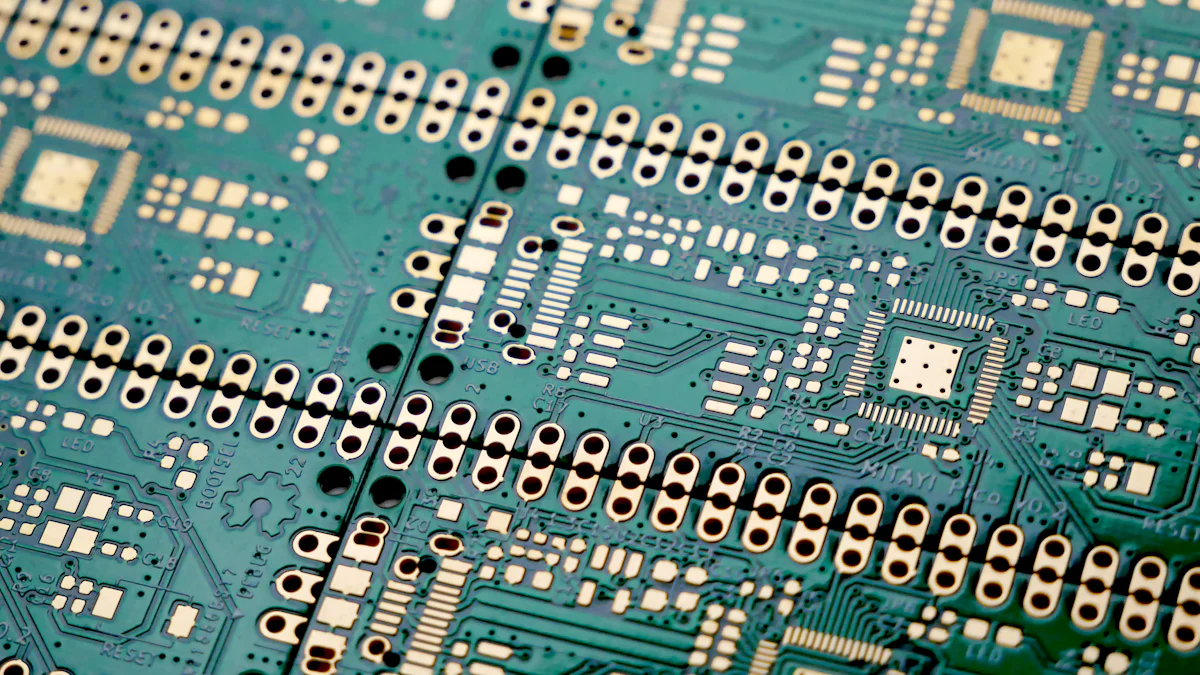

High Component Density

Compact Size

Rigid PCBs boast a compact size, allowing for a high component density on the board. This compact design enables electronics manufacturers to create smaller devices without compromising on functionality or performance.

High-Speed Circuitry Compatibility

With their high-speed circuitry compatibility, rigid PCBs facilitate the seamless operation of electronic systems requiring fast data processing. These boards are ideal for applications where speed and efficiency are paramount.

Cost-Effectiveness

Consistent Quality

Rigid PCBs offer consistent quality across production batches, ensuring reliability and performance consistency in electronic devices. This reliability translates to cost savings for manufacturers by minimizing defects and rework.

Ease of Fabrication and Assembly

The ease of fabrication and assembly associated with rigid PCBs streamlines the manufacturing process, reducing lead times and overall production costs. Manufacturers benefit from efficient production cycles without compromising on quality.

Applications of Rigid PCBs

Consumer Electronics

Computers and Laptops

Computers and laptops extensively utilize rigid PCBs to power their intricate systems. These boards enable the seamless integration of components, ensuring optimal performance in computing devices. The rigid PCBs in computers and laptops facilitate the transmission of data between various parts, enhancing overall efficiency.

Mobile Phones and Tablets

In the realm of mobile technology, rigid PCBs are indispensable components within mobile phones and tablets. These compact boards provide a stable platform for the electronic systems in these devices. By incorporating rigid PCBs, manufacturers can design sleek and lightweight mobile gadgets that deliver exceptional performance.

Medical Devices

High-Reliability Products

The medical industry relies on rigid PCBs to power critical equipment such as diagnostic tools and monitoring devices. The use of these boards ensures the reliability and accuracy of medical instruments, contributing to improved patient care outcomes. Rigid PCBs play a vital role in maintaining the precision and functionality of high-reliability medical products.

Reduced Maintenance Costs

By integrating rigid PCBs into medical devices, healthcare facilities benefit from reduced maintenance expenses. The durability and stability offered by these boards minimize the need for frequent repairs or replacements, resulting in cost savings for medical institutions. Rigid PCBs contribute to the longevity and efficiency of medical equipment, ultimately lowering operational costs.

Industrial and Automotive

Environmental Resistance

Industrial machinery and automotive systems leverage the robust nature of rigid PCBs to withstand challenging environmental conditions. These boards exhibit resilience against factors like temperature variations, moisture, and vibrations, ensuring consistent performance in harsh settings. The environmental resistance of rigid PCBs enhances the reliability and longevity of industrial and automotive applications.

High Performance in Harsh Conditions

In demanding industrial environments or automotive settings, where reliability is paramount, rigid PCBs excel in delivering high performance under extreme conditions. The mechanical strength and thermal stability of these boards enable them to function optimally even in rugged scenarios. By utilizing rigid PCBs, industries ensure uninterrupted operation and enhanced productivity in challenging work environments.

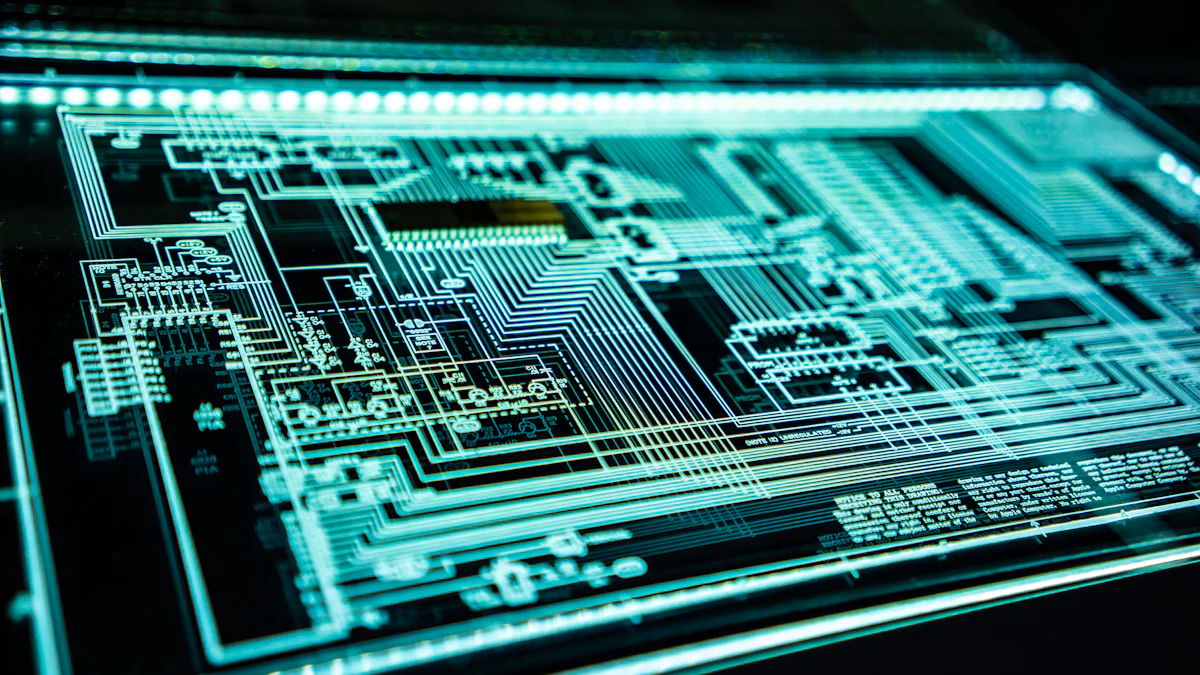

Rigid-Flex PCBs

Advantages of Rigid-Flex PCBs

Improved Reliability

Rigid-flex PCBs offer a unique combination of advantages that set them apart in the realm of electronic design. Improved reliability is a standout feature, ensuring that these boards deliver consistent performance even in demanding applications. By seamlessly integrating rigid and flexible elements, manufacturers can enhance the durability and longevity of electronic systems.

The streamlined assembly process associated with rigid-flex PCBs simplifies manufacturing operations, reducing production complexities and lead times. This efficiency translates to cost savings for companies while maintaining high-quality standards throughout the assembly process. The seamless integration of rigid and flexible components optimizes the overall functionality of electronic devices, making them more reliable and efficient.

Expert insights from Antti, a specialist in PCB design, emphasize the significance of rigid-flex PCBs in enhancing design reliability. According to Antti, these boards offer numerous advantages over traditional rigid or flexible designs, making them a preferred choice for modern electronic applications.

Siemens Electronic Systems Design highlights the future-forward nature of rigid-flex PCB technology, citing its compelling blend of performance, reliability, and flexibility as key drivers shaping the future of electronic engineering. As printed circuit engineers continue to innovate and collaborate in this field, the potential for rigid-flex technology remains limitless.

In portable electronics design, careful consideration is essential when incorporating rigid-flex PCBs due to their hybrid nature. These boards provide a balance between flexibility, mechanical stability, and space-saving capabilities—ideal for compact devices requiring durability and efficient thermal management.

One-Stop Rigid-flex PCB Manufacturing

Reduced Production Costs

Enhanced Product Performance

One-stop solutions for rigid-flex PCB manufacturing offer a comprehensive approach to meeting industry demands efficiently. By consolidating production processes into a single source, companies benefit from reduced production costs without compromising on quality or performance. This streamlined approach optimizes resource utilization and accelerates time-to-market for innovative electronic products.

The integration of rigid and flexible elements in manufacturing leads to enhanced product performance, elevating the functionality and reliability of electronic systems. Rigid-flex PCBs enable designers to push boundaries in product development by creating versatile solutions that excel in diverse applications—from consumer electronics to industrial machinery.

Through collaborative efforts and continuous innovation within the field of rigid-flex technology, manufacturers can unlock new possibilities for advanced electronics design. The versatility and adaptability of these boards pave the way for cutting-edge solutions that cater to evolving market needs while ensuring optimal performance across various industries.

In summary, Rigid PCBs offer a multitude of benefits in electronics, including durability, high component density, and cost-effectiveness. These boards are integral to various applications such as consumer electronics, medical devices, and industrial machinery. The significance of Rigid PCBs in modern electronics cannot be overstated, as they ensure reliability and performance consistency across diverse systems. Looking ahead, the future potential of Rigid PCBs is promising, with advancements like Rigid-Flex PCBs enhancing design reliability and enabling innovative product development.